Staff profile

Emma Gillard

PGR Student

| Affiliation |

|---|

| PGR Student in the Department of Physics |

Biography

Biography

I am a PhD student doing an experimental project that investigates the use of High Temperature Superconductors for fusion reactor applications. Before my PhD, I completed an integrated Masters degree in physics at Oxford University in 2021 and am now doing my PhD as a member of the Durham University Superconductivity Group. In doing this PhD, I also form part of the EPSRC Centre for Doctoral Training in the Science and Technology of Fusion Energy, based in York (http://www.fusion-cdt.ac.uk/). This Fusion CDT is a collaboration between five world-class universities that work with non-academic partners to train PhD students to build essential fusion knowledge.

Research Interests

Introduction

REBCO (Rare earth Barium Copper Oxide) is a commercially produced high temperature superconductor that is considered for use in the magnet system of a fusion reactor. It is manufactured as a tape, with the thin superconductor layer deposited onto a substrate [1]. The superconductor is characterised by three critical parameters, its critical current, critical magnetic field and critical temperature. To enable compact plasma confinement, REBCO must produce a high magnetic field and therefore have a high critical current [2], however the critical current is known to degrade with temperature, magnetic field, strain and angle of the tape normal to the field [3], [4]. In a fusion reactor, there are very high fields, and high strains upon cooling and Lorentz forces of the magnet system [5], and these conditions can degrade the critical current of REBCO and hence limit its performance as a magnet in a reactor. Therefore, measuring the dependence of the critical current of REBCO on temperature, magnetic field and strain is essential to enable the use of REBCO in future fusion facilities.

Experimentation

The work I do is to experimentally measure the critical current density of REBCO under various temperatures, magnetic fields, angles of the tape normal to the field, and strains. Small 7mm by 4mm samples of tape are cut and soldered to a strain-board designed and built in Durham. The strain-board projects strain into the sample by tightening a central screw, causing a small compressive bending strain that can reach up to -1% strain. The sample is then placed into a cryogenic system (Cold Head) held under vacuum that can measure and vary the temperature of the sample down to 4K. Standard four-terminal measurements are used to generate V-I traces and determine the critical current. To enable small currents to be used in these measurements, which are easier to generate and produce less heating, a process of chemical etching followed by focussed ion beam milling (FIB) is used to create narrow tracks of superconducting REBCO down to 5 micrometers.

Key Results

In 2022 I measured the dependence of the critical magnetic field of REBCO on temperature, strain and angle using a Physical Properties Measurement System (PPMS) that can reach fields of up to 8T. I found that, although there was a strong dependence on angle and temperature, there was very little dependence of the critical field on strain, and this was attributed to the fact that very small currents were used to measure the sample resistance and represented the parts of the tape with the highest critical parameters.

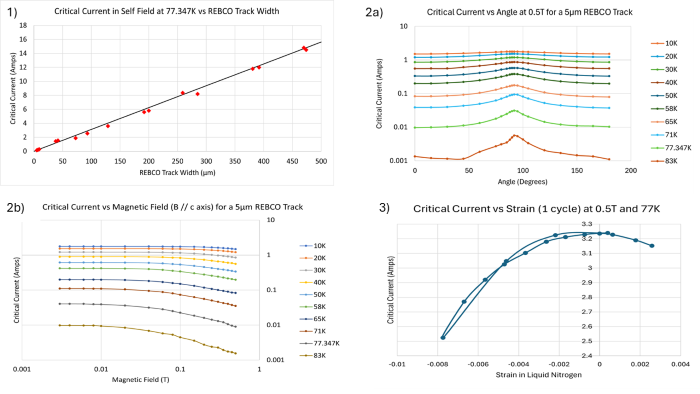

In 2024 I have been working to refine the track production technique and confirmed that the critical current scales with the track width (see Fig. 1). I have measured the critical current dependence on field (between 0T and 0.5T), temperature (between 10K and 83K) and angle using the Cold Head on 5 micrometer wide tracks made using FIB (see Fig. 2a & b). I am working towards confirming the parabolic dependence of the critical current on strain (see Fig. 3) for the narrow tracks and investigating the robustness of the samples to degradation mechanisms, including thermal cycling.

Future Work

- To design an in-situ variable strain device to be commissioned in the Cold Head and allow for in-situ strain measurements.

- Continue to investigate the degradation mechanisms of REBCO.

- Investigate the effect of strain cycling on the REBCO tracks using liquid nitrogen.

- Map out the critical surface of REBCO tracks for fields up to 0.5T, temperatures between 10K and 83K, all angles and strains between -0.5% and 0.5%.

References

[1] Superpower, “2G HTS Wire Specification.” Accessed: Oct. 09, 2023. [Online]. Available: https://www.superpower-inc.com/specification.aspx

[2] D. G. Whyte, J. Minervini, B. LaBombard, E. Marmar, L. Bromberg, and M. Greenwald, “Smaller & Sooner: Exploiting High Magnetic Fields from New Superconductors for a More Attractive Fusion Energy Development Path,” Journal of Fusion Energy, vol. 35, no. 1, pp. 41–53, Feb. 2016, doi: 10.1007/s10894-015-0050-1.

[3] J. R. Greenwood, E. Surrey, and D. P. Hampshire, “The Biaxial Strain Dependence of JC of a (RE)BCO Coated Conductor at 77 K in Low Fields,” IEEE Transactions on Applied Superconductivity, vol. 29, no. 5, Aug. 2019, doi: 10.1109/TASC.2019.2898343.

[4] C. W. A. Gurnham, V. Große, and D. P. Hampshire, “Angular J c measurements at 77 K in-field, on an ISD REBCO coated conductor using a straightforward mechanical scribing technique to reduce tape width.”

[5] P. Branch, Y. Tsui, K. Osamura, and D. P. Hampshire, “Weakly-Emergent Strain-Dependent Properties of High Field Superconductors,” Sci Rep, vol. 9, no. 1, Dec. 2019, doi: 10.1038/s41598-019-50266-1.

Activities

Experience:

- Work experience at the International Thermonuclear Experimental Reactor (ITER) from 1st June to 31st July 2024. Cadarache, France.

Poster Presentations:

- FuseNet PhD Event 2023, 23rd – 25th August 2023, Lausanne, Switzerland.

- Applied Superconductivity Conference 2022, 23rd – 28th October 2022, Honolulu, Hawaii, USA.

Oral Presentations:

- Nuclear Institute YGN Speaking Competition National Final, 27th September 2022, Warrington, UK.

- Nuclear Institute North East Branch 2022 YGN Speaking Competition, 2nd August 2022, Durham, UK.

Publications

Journal Article

- Resistivity Measurements of the Strain, Temperature and Angular Dependence of the Upper Critical Field of REBCO Tapes up to 8 TGillard, E., Raine, M., & Hampshire, D. (2023). Resistivity Measurements of the Strain, Temperature and Angular Dependence of the Upper Critical Field of REBCO Tapes up to 8 T. IEEE Transactions on Applied Superconductivity, 33(5). https://doi.org/10.1109/tasc.2023.3273198