Flexible Heat and Power

High efficiency fuel flexible free piston engine generator

All sectors are seeking to decarbonise power generation through reduced emission and highly efficient technology at low-cost. Durham University’s on-going R&D portfolio around free piston engine (FPE) technologies can satisfy this requirement and has demonstrated the potential for very high electrical efficiency relative to current market leading solutions and can switch between liquid and gaseous fuels, such as gasoline, bioethanol and hydrogen.

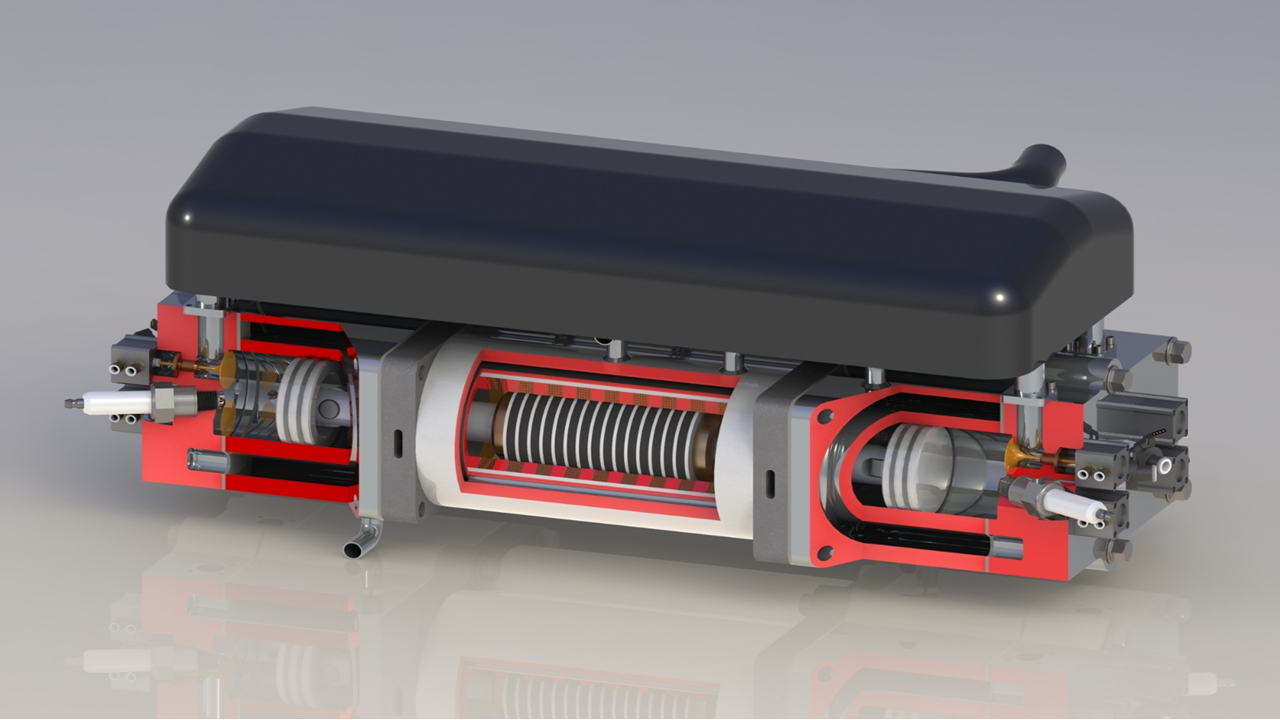

Free piston engine generators have the potential to realise a more fuel efficient solution (42-55% thermal efficiency for a spark ignition mode) than conventional state-of-the-art reciprocating engines. In addition, it offers a greater scope for fuel-flexibility, including the potential of real time switching between the typical fuels (and blends). Durham University’s FPE Prototype, is the result of over 10 years of R&D; the technology is based around two engine cylinders, which fire alternately and are coupled mechanically via a linear shaft/stator.

Free Piston Engine Technology

The technology is 60% smaller and 25% lighter than a conventional internal combustion engine (ICE) generator and similar advantages over fuel cell technology. It has proven thermal efficiencies of between 40 and 50% and 30% higher electrical efficiency than existing reciprocating IC engine generators and similar electrical efficiency as existing PEM fuel cells. The system can operate either in 2 or 4 stroke mode, switch between liquid and gaseous fuels – even during operation. It has the potential of transition from low-carbon to zero-carbon fuels (i.e. bioethanol and hydrogen).

Other advantages include:

-

Variable compression ratio, fuel injection and valve timing - controllable without physical changes.

-

Robust to variations in fuel quality and contamination.

-

Future proof against changes to their supply and availability.

-

Very few moving or highly stressed components

-

No piston slap, no rotary components – reduced noise

-

Cheaper to manufacture and maintain than ICE or Fuel Cell

-

Higher reliability and availability

-

Lower frictional and heat transfer losses than conventional IC engines.

This innovative technology was developed at Durham Energy Institute by Professor Tony Roskilly (Principal Investigator) and Dr Sumit Roy (Early Career Researcher) as a part of their Innovate UK project.

Application of Free Piston Engines

Free piston engine technology achieving the desired efficiency, compactness, low cost and fuel flexibility will have a number of applications:

DEI Free Piston Combined Heat and Power Technology

DEI Free Piston Electric Power Generator Technology for Transport

Free Piston Engine Generator Concept

The technology focuses on the development of an ultra-high efficiency, fuel flexible electric generator for multiple applications.

It is based on patented free-piston engine generator (FPEG) design. From detailed analysis and prototype testing, compared to a conventional engine generator, a FPEG offers the potential of

(a) 30% lower fuel consumption

(b) 25% weight reduction

(c) 60% volume reduction

(d) flexibility to switch between different gaseous and liquid fuels (in real time).

The prototype FPEG (TRL4) consists of a double-acting piston and cylinder with an integrated linear generator. The linear generator is used to convert the linear motion of the moving pistons to electrical power directly.

Advantages:

(a) cheaper, compact and lightweight machine without a need for a crankshaft and crank case

(b) improved maintainability and availability through a reduction in friction and moving components

(c) enhanced piston and linear generator motion electrically rather than mechanically controlled enabling variable compression ratio (fuel flexibility) and operation closer to the ideal thermodynamic cycles (improved thermal efficiency).

A FPEG has the potential to realise an equivalent electrical efficiency to a PEM fuel cell and be significantly cheaper, more robust and able to operate with a wide range of fuels. The prototype spark ignited FPEG has demonstrated switching from gasoline to hydrogen operation and the possibility of a thermal efficiency of up to 55%.

/prod01/prodbucket01/media/durham-university/research-/research-institutes/durham-energy-institute/landscapes-cityscapes-montages-etc/Walney-sunset-2000X800.jpg)

/prod01/prodbucket01/media/durham-university/research-/research-institutes/durham-energy-institute/technologies/engines--drivetrains/FPEG-CHP-video-image.png)

/prod01/prodbucket01/media/durham-university/research-/research-institutes/durham-energy-institute/technologies/engines--drivetrains/FPEG-for-Transport-video-image.png)